Overseas production

We can oversee a complete manufacturing of your device produced by our overseas contract manufacturer.

We utilize companies described below for

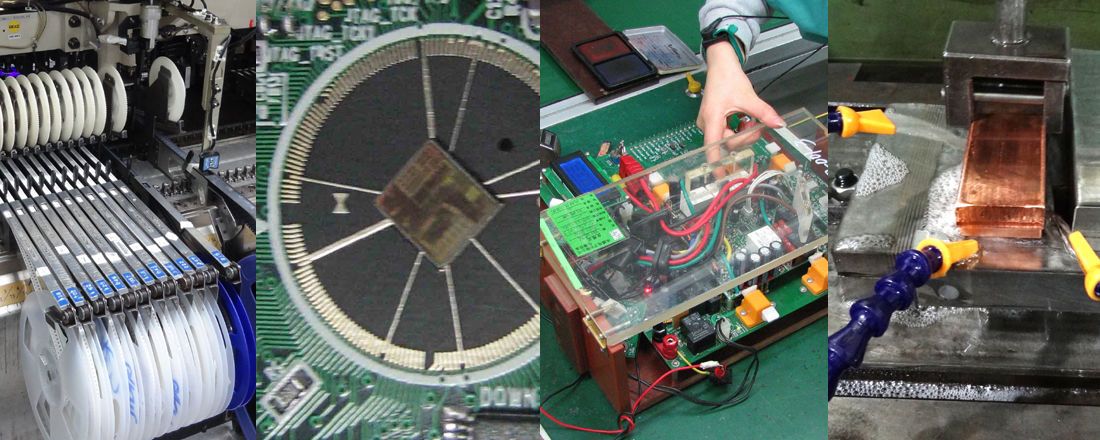

For the complete assembled product we utilized Whitways as one of our offshore manufacturers. They apply highest level of manufacturer quality specification to your product. Their High speed pick and place machine is capable to place 100K components per hours. After completion of the PCB assembly an automated visual inspection is performed. This is followed by a full functional test.

The quality and of the solder paste and accuracy of the stencil is checked by an optical system.

For your product components we utilized companies described below:

For PCB manufacturing we use

Greenteke Inc. They are top quality and most reliable board supplier. They utilize fling probe to test the prototype board against the netlist from the Gerber file. Four heads drilling and routing machine can do up to five layers of the boards at the same time.

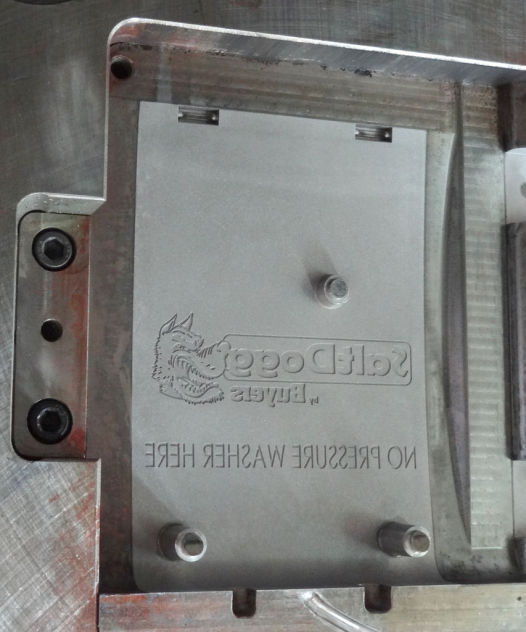

Ningbo SYL Precision Metals Co.,Ltd is the mould manufacturer.

The first step of the mold making they create a master copper model of the plastic part for electroforming process . They utilized high quality steel for their injection plastic mould.

They prepare a decorative logo engraving and final surface finish as the last step of the mould making. It takes up to 6 weeks to get the finished injection plastic part .

Gallery

![[X]](img/x.png)